Modern manufacturing premises

In our new premises we manufacture 3 million plastic mouldings every day, using modern working standards and maximum automation.

Injection moulding machines

We have a range of 36 modern press machines in the tonnage range of 60 – 240 tons with all necessary components. We have also 2K injection moulding machines available.

Material drying

The most advanced computer-controlled drying ensures optimal preparation of the material which is then transferred directly to the injection moulding machine.

Expedition warehouse

Thanks to the space-saving mobile warehouse, the expedition of products is easier and faster.

Kitchen area

The newly built facility includes a welcoming kitchen area. We are happy to offer subsidized meals to our employees.

Warehouse of material

Mould warehouse

Each mould is stored in its place after performing the maintenance.

Quality control

We verify the quality of manufactured mouldings using a 3D optical measuring instrument and other equipment.

Finishing plant

We also provide minor assemblies and packaging according to customer requirements.

Moulding plant

We emphasize high standards of cleanliness and tidiness.

- Warehouse and material receipt

- Manufacture of mouldings

- Finishing plant

- Warehouse and shipment of mouldings

Central material distribution

Preparation and distribution of material is automated, which enables effective manufacturing and a minimal error rate.

Energy savings of up to

40%

Equipment used

-

Sorting unit

Distribution unit with a decoding device absolutely excludes mistakes in the material

-

Dryer

Top modern molecular sieve dryer ensures the optimum preparation of material for manufacturing.

-

Distribution

Modern distribution system ensures fast and precise transport of material to individual machines

-

Hopper and colouring device

Vacuum hoppers and a volumetric colouring device ensure consistency in the amount of material and colour of components

-

Injection press

We have 36 Battenfeld and Negri Bossi machines, with a tonnage of 60 to 240 tonnes, all of which are equipped with peripheries and numericaly controled. We also have 2K injection machines.

-

Crusher

In each machine we can use low-speed, dust-free crushers, which enable us to implement waste-free manufacturing.

CLOSED PRESSING SYSTEM

Waste-free manufacturing

The environment is our priority, and therefore our manufacturing is strictly waste-free.

At the customer’s request we can provide a closed pressing system, which guarantees maximum use of material.

Our product care

PRECISION OF MEASUREMENT

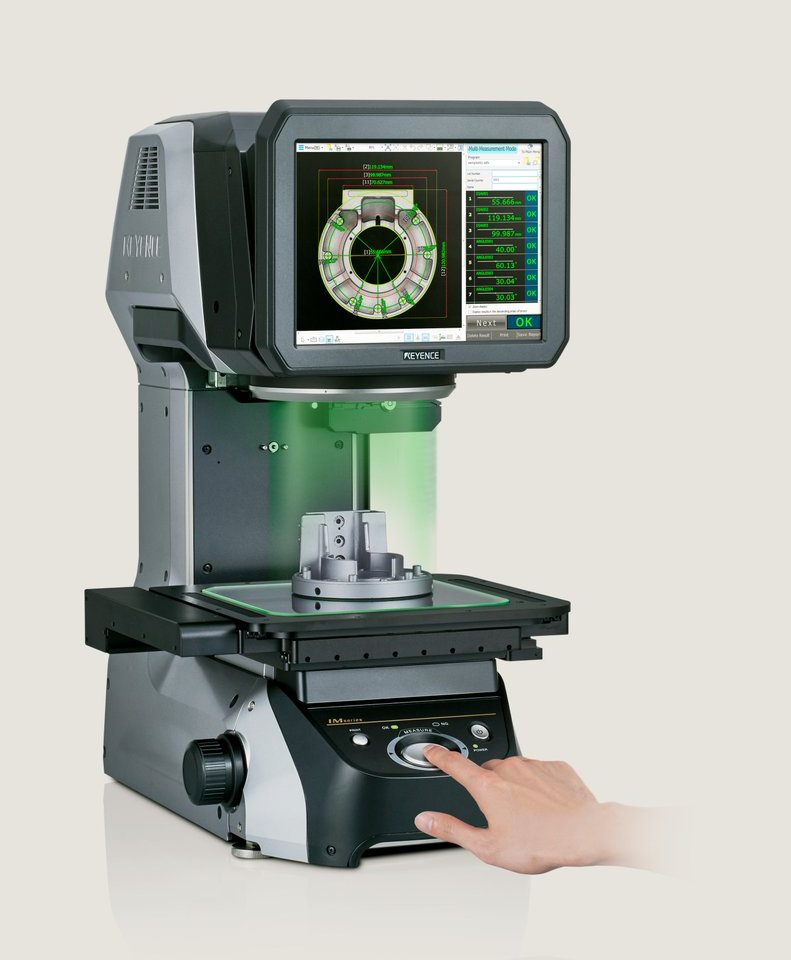

Digital Profile Projector

Keyence IM-7000 - Digital Profile Projector

- automatic identification of measuring points ensures that the same measurement results are always obtained

- automatic data logging and reporting

- measuring dimensions at specified heights

PRECISION OF MEASUREMENT

Quality management

An optical measurement device controls 99 various specific dimensions. It compares them with a 3D model with one click.

PRECISION OF MEASUREMENT

Roughness and Contour Measurement

Diavite DH - 8 - Roughness and Contour Measurement. We use a roughness and contour measuring device from the Swiss manufacturer DIAVITE including Diasoft software

STORAGE AREAS

Warehouse management

Mobile storage enables considerable space saving. We have room for 3,000 pallets. The warehouse is linked directly to our internal bar code system, which enables us to implement FIFO.

MANUFACTURING AND STORING

Care for moulds

Taking care of our customers’ moulds is one of our priorities. The moulds receive regular maintenance and dry ice cleaning. We keep the moulds in a modern shelving system.

OUR SERVICES

What are we offering you?

Our aim is customer satisfaction. From assistance in constructing the products, selection of suitable material, manufacture of the mould and test samples to mass production.

What we do